Clamp

Classification:

Clamp is a versatile mechanical tool designed to hold objects tightly together to prevent movement or separation during assembly, repair, manufacturing, or other industrial and DIY tasks. By applying controlled pressure, clamps ensure stability, accuracy, and safety, making them indispensable in both professional workshops and home garages. Unlike temporary fastening methods such as tape or string, clamps deliver consistent and adjustable pressure, adapting to different shapes, sizes, and materials of the objects being secured.

One of the most notable features of clamps is their Secure Grip, which is achieved through thoughtful design elements like non-slip jaws, adjustable pressure knobs, and sturdy frame structures. For example, bar clamps use a long, rigid bar and a sliding jaw to distribute pressure evenly across large surfaces, making them ideal for woodworking projects like gluing table tops or cabinet doors. C-clamps, with their compact "C" shaped frame and threaded screw, provide a strong grip on smaller objects, such as holding metal parts in place during welding or drilling. This secure grip prevents slippage, ensuring that workpieces remain aligned and reducing the risk of errors or accidents.

Versatility is another key advantage of clamps, as they come in a wide range of types to suit various applications. Beyond bar clamps and C-clamps, common varieties include pipe clamps for securing cylindrical objects like pipes or rods, spring clamps for quick, light-duty tasks such as holding fabric or paper, and toggle clamps for automated, repeatable fastening in manufacturing lines. This diversity allows clamps to be used across industries—from construction and automotive repair to crafting and electronics assembly. A single workshop might use multiple clamp types, each tailored to specific tasks, highlighting their ability to adapt to different work requirements.

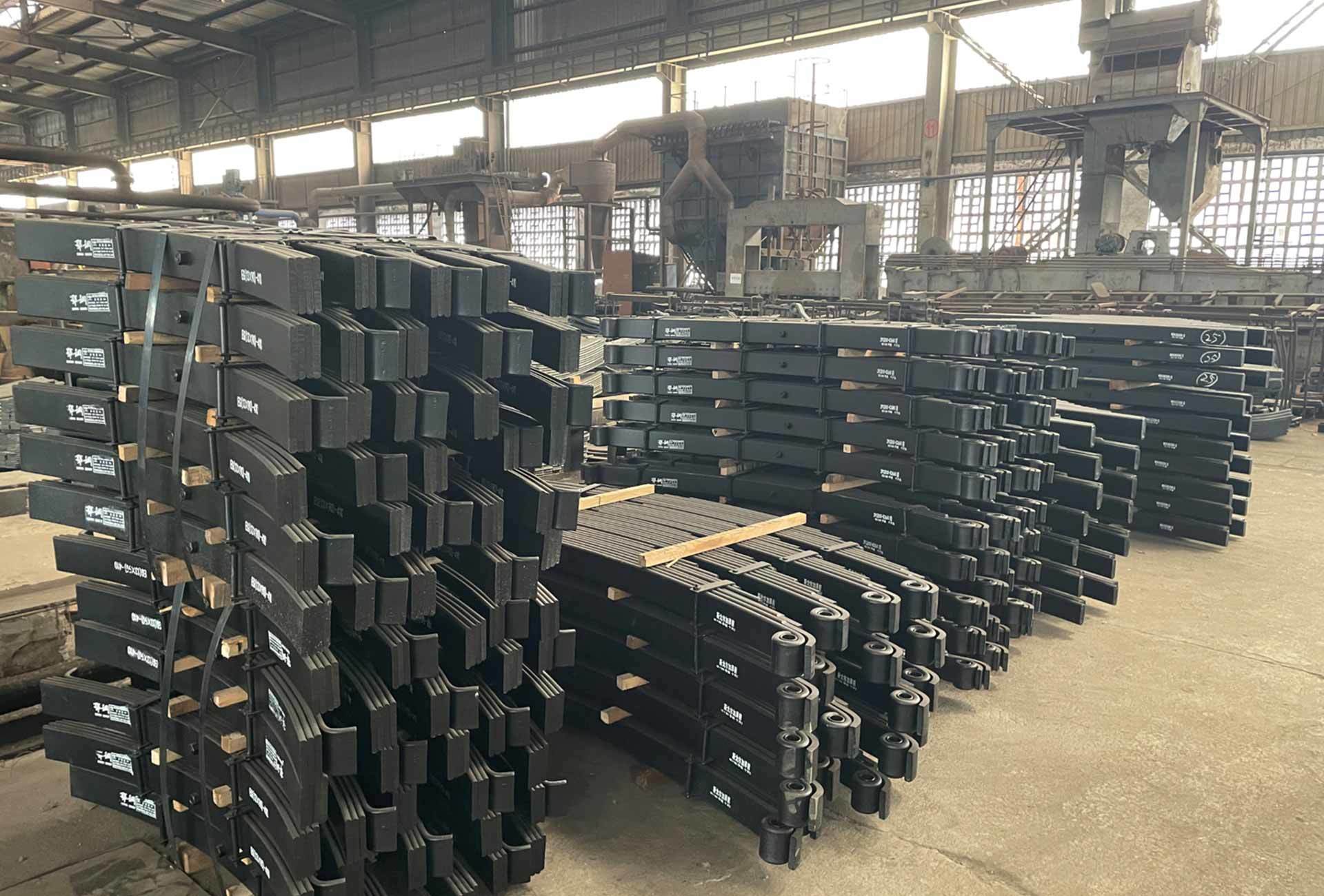

Durability is a critical characteristic of high-quality clamps, often linked to their High-Strength Materials. Most professional-grade clamps are made from materials like hardened steel, aluminum alloy, or reinforced plastic, which can withstand heavy pressure, frequent use, and exposure to harsh conditions. Steel clamps, for instance, resist bending and corrosion, making them suitable for outdoor construction or industrial environments where moisture or chemicals may be present. Aluminum clamps, while lighter, still offer excellent strength, making them easy to transport and handle for on-site work. This durability ensures that clamps have a long service life, providing value for both professionals and hobbyists.

Ease of Use is also an important factor in clamp design, as it enhances efficiency and reduces user fatigue. Many modern clamps feature ergonomic handles that provide a comfortable grip, even during extended use. Quick-release mechanisms, found in some bar clamps and pipe clamps, allow users to adjust the jaw position rapidly without rotating the screw repeatedly, saving time when switching between workpieces. Additionally, some clamps come with removable or interchangeable jaws, enabling them to grip irregularly shaped objects or protect delicate surfaces (like wood or plastic) from scratches. These user-friendly features make clamps accessible to people of all skill levels, from beginners to experienced tradespeople.

Contact:

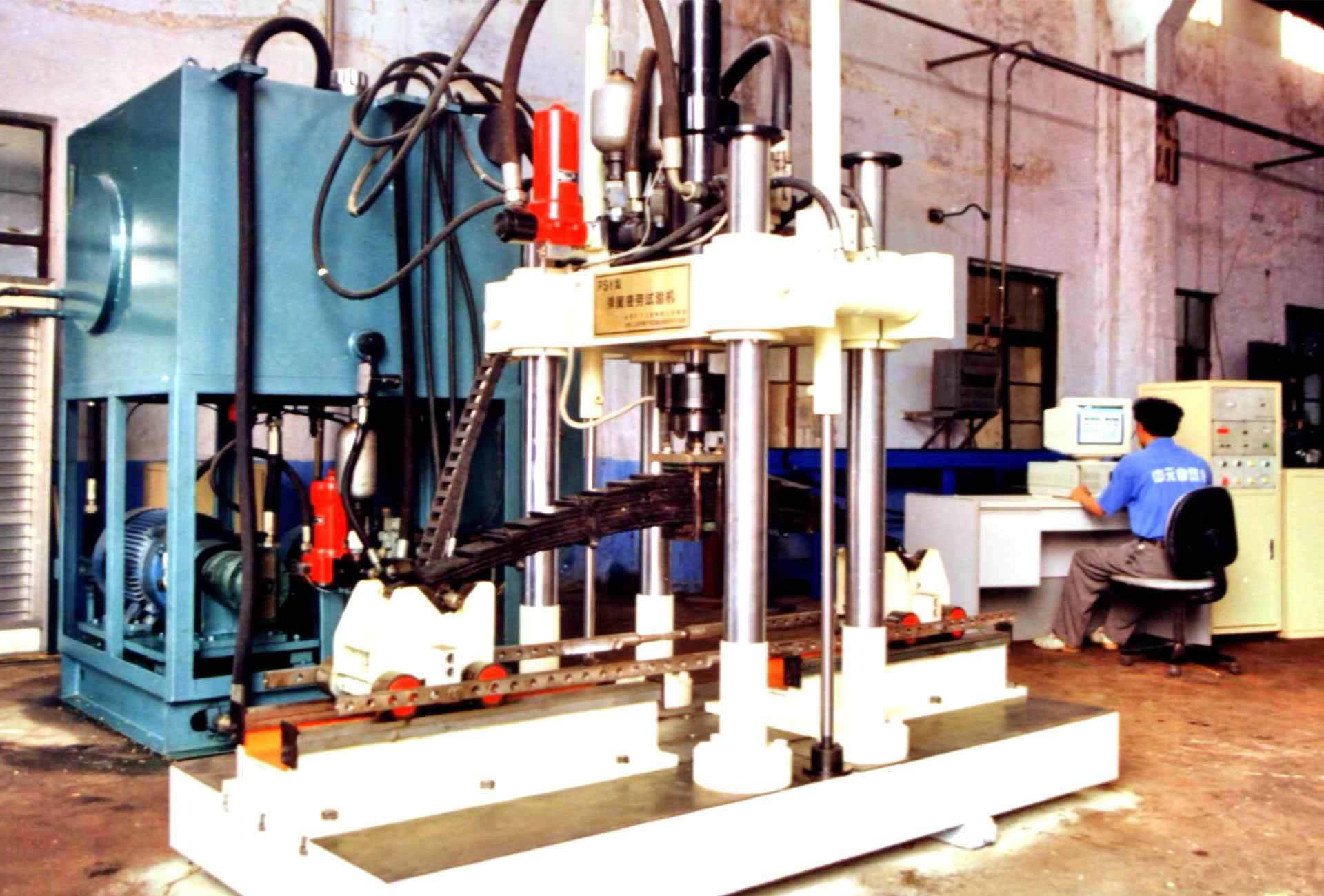

FACTORY STRENGTH

Message consultation